- Home

- Sustainability

- Environment

- Environmental Initiatives

- Reducing Emissions of Environmentally Harmful Substances

Reducing Emissions of Environmentally Harmful Substances

- Measures to Prevent Air Pollution

- Measures to Control Coal Dust, etc.

- Measures to Prevent Malodor

- Measures to Control Thermal Water Discharge

- Measures to Prevent Water Pollution

- Cutting Back on Industrial Water Use

- Measures to Prevent Soil Pollution

- Measures to Prevent Oil Leaks

- Measures to Prevent Noise and Vibration

The J-POWER Group undertakes environmental preservation initiatives using the latest technologies and knowledge to reduce the environmental burden caused by its domestic and overseas electric power businesses.

Measures to Prevent Air Pollution

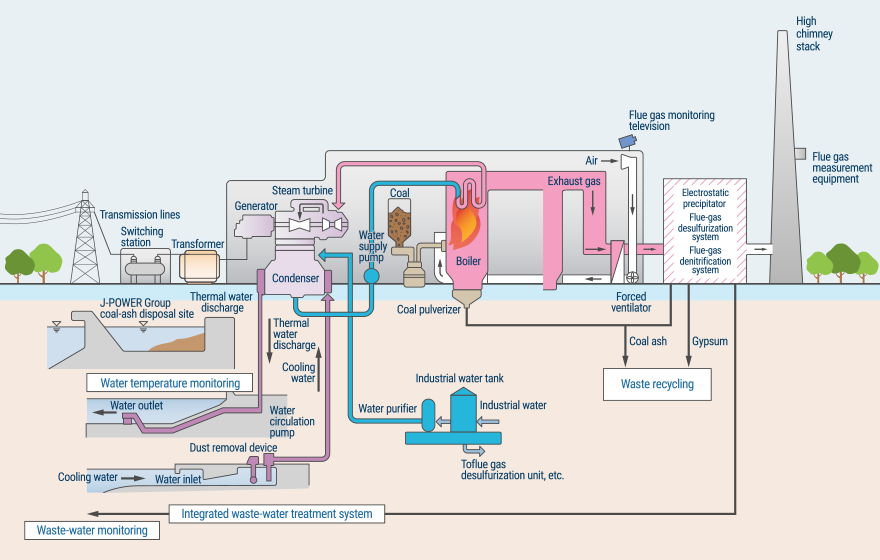

The combustion of coal and other fuels can generate sulfur oxides (SOx), nitrogen oxides (NOx), and soot and dust. To eliminate these emissions, we take such measures as improving combustion methods and always making appropriate use of such flue gas treatment equipment as desulfurization and denitrification systems and electrostatic precipitators. In this way, we achieve highly efficient pollutant reduction. This equipment operates automatically with the aid of measurement devices that continuously monitor the content of flue gas.

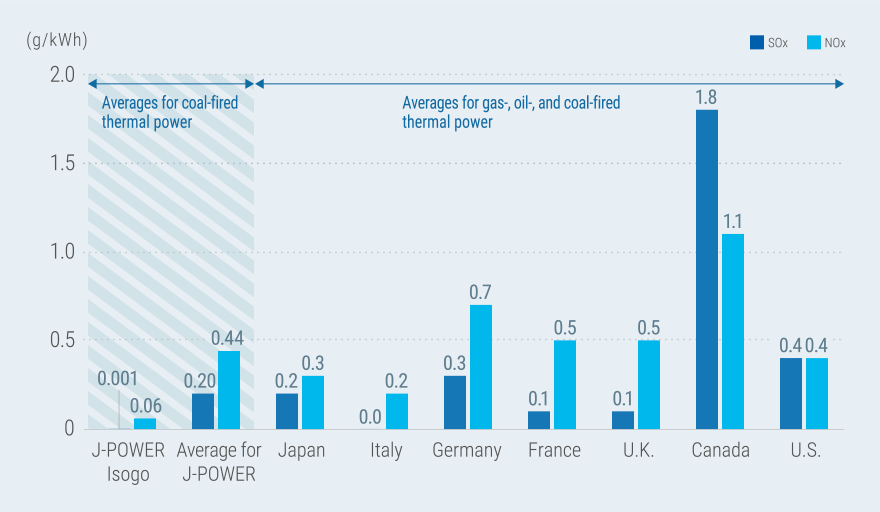

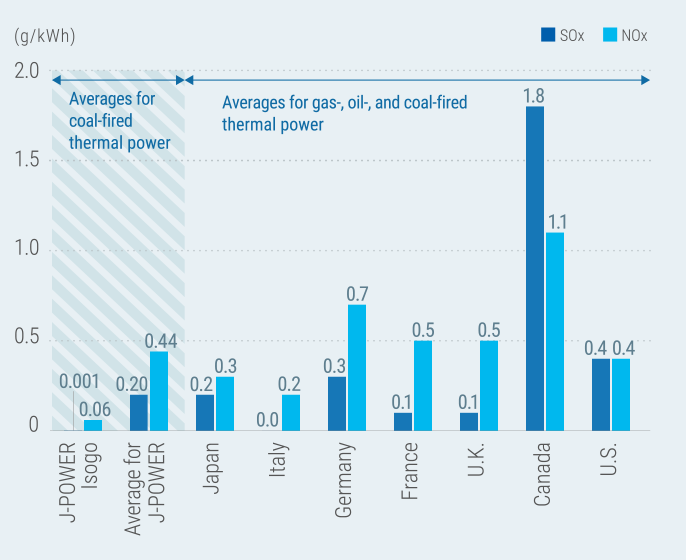

Our fiscal 2020 performance regarding SOx, NOx, and soot and dust emissions is shown in the below table. The figures obtained are quite low by international standards.

International Comparison of SOx and NOx missions Intensity for Thermal Generation

Notes:

- 1.Emissions: OECD StatExtracts Power generated: IEA “Energy Balances of OECD Countries 2019 Edition”

- 2.J-POWER and Isogo figures are fiscal 2020 results.

Measures to Control Coal Dust, etc.

We implement various measures to prevent the dispersal of dust during the handling of coal and coalash, including the use of closed convey or belts and silos,as well as windshielding and spraying with water as dictated by topographical and weather conditions. At our coal ash landfill disposal sites, soilis spread over the surface, and leachate is treated with appropriate treatment systems.

Measures to Prevent Malodor

Since ammonia is added to flue gas denitrification system, we pay attention to prevent leakage from ammonia-using equipment and receiving storage facilities equipment through daily inspections.The magnitude of malodor measured regularly at the boundary of the site to ensure that it remains at or below the reference values.

Measures to Control Thermal Water Discharge

Seawater taken in to cool the steam used in power generation is released as thermal water discharge.* We control intake and discharge properly to minimize their impact on marine life in the vicinity and monitor the temperature of thermal water discharge on a 24-hour basis to ensure that it remains at or below the reference values established under environmental protection agreements.

※Thermal water discharge:

In thermal power generation, the steam that drives the turbine is sent through a condenser for cooling, returning to its liquid state for reuse in the boiler. In almost all power stations in Japan, seawater is used for cooling in the condensers. As the seawater cools the steam passing through the condenser, its temperature rises. It is then returned to the ocean through the discharge outlet, at which point it is referred to as thermal water discharge.

Measures to Prevent Water Pollution

Wastewater from such facilities as desulfurization units and offices is appropriately treated in integrated wastewater treatment systems using such processes as coagulation, precipitation, and filtration. Treated water is always monitored by automatic measuring equipment and analyzed periodically to ensure that it meets the standards set under the Water Pollution Prevention Act and environmental protection agreements.

Cutting Back on Industrial Water Use

Industrial water is used in such equipment as boilers, cooling systems, andwet-type desulfurization systems. Part of this water is released into the atmosphere as steam We work to recover and reuse as much of the wastewater not released into the atmosphere as possible in order to reduce our consumption of industrial water.

Measures to Prevent Soil Pollution

From fiscal 2004 through 2006, we conducted studies at allJ-POWER Group domestic sites and determined that they were free of soil and groundwater contamination. We will continue working diligently to ensure that no soil pollution occurs.

Measures to Prevent Oil Leaks

We implement various measures to prevent the leakage and dispersion of fuel oil, lubricating oil,and other such substances within power station grounds, including keeping adsorbent materials constantly ready.

Measures to Prevent Noise and Vibration

The boilers, turbines, air blowing fans are installed in a building to prevent noise and vibration.We installed soundproof covers and soundproof walls for outside facilities are installed as required.The magnitude of noise and vibrationis measured regularly at the boundary of the site to ensure that it remains at or below the reference values.

Measures to Prevent Noise and Vibration

The boilers, turbines, air blowing fans are installed in a building to prevent noise and vibration. We installed soundproof covers and soundproof walls for outside facilities are installed as required. The magnitude of noise and vibration is measured regularly at the boundary of the site to ensure that it remains at or below the reference values.

Measures to Prevent Air Pollution

The combustion of coal and other fuels can generate sulfur oxides (SOx), nitrogen oxides (NOx), and soot and dust. To eliminate these emissions, we take such measures as improving combustion methods and always making appropriate use of such flue gas treatment equipment as desulfurization and denitrification systems and electrostatic precipitators. In this way, we achieve highly efficient pollutant reduction. This equipment operates automatically with the aid of measurement devices that continuously monitor the content of flue gas.

Our fiscal 2020 performance regarding SOx, NOx, and soot and dust emissions is shown in the below table. The figures obtained are quite low by international standards.

Measures to Prevent Malodor

Since ammonia is added to flue gas denitrification system, we pay attention to prevent leakage from ammonia-using equipment and receiving storage facilities equipment through daily inspections. The magnitude of malodor measured regularly at the boundary of the site to ensure that it remains at or below the reference values.

Measures to Control Coal Dust, etc.

We implement various measures to prevent the dispersal of dust during the handling of coal and coal ash, including the use of closed conveyor belts and silos, as well as windshielding and spraying with water as dictated by topographical and weather conditions. At our coal ash landfill disposal sites, soil is spread over the surface, and leachate is treated with appropriate treatment systems.

Measures to Control Thermal Water Discharge

Seawater taken in to cool the steam used in power generation is released as thermal water discharge.* We control intake and discharge properly to minimize their impact on marine life in the vicinity and monitor the temperature of thermal water discharge on a 24-hour basis to ensure that it remains at or below the reference values established under environmental protection agreements

Measures to Prevent Water Pollution

Wastewater from such facilities as desulfurization units and offices is appropriately treated in integrated wastewater treatment systems using such processes as coagulation, precipitation, and filtration. Treated water is always monitored by automatic measuring equipment and analyzed periodically to ensure that it meets the standards set under the Water Pollution Prevention Act and environmental protection agreements.

Cutting Back on Industrial Water Use

Industrial water is used in such equipment as boilers, cooling systems, and wet-type desulfurization systems. Part of this water is released into the atmosphere as steam. We work to recover and reuse as much of the wastewater not released into the atmosphere as possible in order to reduce our consumption of industrial water.

Measures to Prevent Soil Pollution

From fiscal 2004 through 2006, we conducted studies at all J-POWER Group domestic sites and determined that they were free of soil and groundwater contamination. We will continue working diligently to ensure that no soil pollution occurs.

Measures to Prevent Oil Leaks

We implement various measures to prevent the leakage and dispersion of fuel oil, lubricating oil, and other such substances within power station grounds, including keeping adsorbent materials constantly ready.