|

|

| |

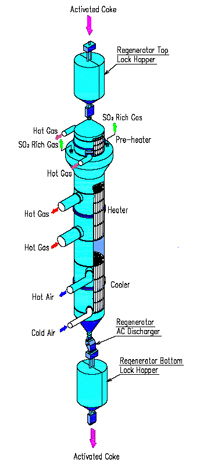

After the AC absorption is saturated with pollutants, the AC is conveyed to the regenerator through a bucket elevator. The regenerator operates at temperature in the rage of 400 to 500oC (750 to 930oF), where the adsorbed sulfuric acid and ammonium compounds in the AC are decomposed to N2, SO2 and water. Mercury is retained in the AC around the top of the regenerator and will be removed with the AC every few years (during facility shutdown), depending on the mercury concentration on the inlet to ReACT. After the AC absorption is saturated with pollutants, the AC is conveyed to the regenerator through a bucket elevator. The regenerator operates at temperature in the rage of 400 to 500oC (750 to 930oF), where the adsorbed sulfuric acid and ammonium compounds in the AC are decomposed to N2, SO2 and water. Mercury is retained in the AC around the top of the regenerator and will be removed with the AC every few years (during facility shutdown), depending on the mercury concentration on the inlet to ReACT.

After cooling, the regenerated AC from the regenerator passes through the separator (vibrating screen) to eliminate degraded AC and captured dust, then returned to the adsorber.

The degraded AC can be burnt in a boiler or can be also sold as other industrial applications, such as dioxin adsorbent.

SO2-rich gas (by-product of AC regeneration) from the regenerator can be converted to a salable product, such as sulfuric acid or gypsum, in the by-product recovery facility. |

| |

|

| |

|