|

|

| |

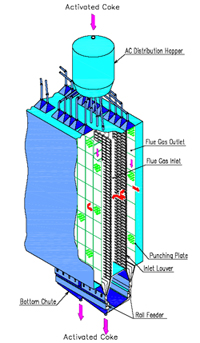

In the adsorber, the flue gas passes through a bed of activated coke (AC), while the AC moves slowly downwards at a constant flow rate. The adsorber is a single-stage or two-stage tower, depending on the design. In the adsorber, the flue gas passes through a bed of activated coke (AC), while the AC moves slowly downwards at a constant flow rate. The adsorber is a single-stage or two-stage tower, depending on the design.

Removal of SOx, NOx, mercury and particulates takes place in the adsorber as follows.

Desulfurization:

SOx is adsorbed in the form of sulfuric acid or ammonium salts on the surface of AC.

| Sulfuric acid: |

|

SO2 + 1/2O2 + H2O → H2SO4 * |

| |

|

SO3 + H2O → H2SO4 * |

| Ammonium salts: |

|

H2SO4 * + NH3 → NH4HSO4 * |

| |

|

NH4HSO4 * + NH3 → (NH4)2SO4 * |

| |

|

*: Adsorption |

Denitrification:

NOx is reduced into N2 through the catalytic reaction of ammonia and AC:

| NO + NH3 + 1/4 O2 → N2 + 3/2H2O |

|

(Catalytic Reduction) |

| NO + NHxO-AC → N2 + H2O + OH-AC |

|

(Reduction on the surface of AC) |

| |

|

|

| (NHxO-AC: One of NOx reducing Compounds on the surface of the AC) |

Mercury removal:

Heavy metals such as mercury in gaseous form are adsorbed on the surface of AC. Elemental mercury are removed as efficiently as ionized and oxidized.

| Hg0 → Hg0* |

|

Hg + H2SO4 * → HgSO4 * |

| HgCL → HgCL* |

|

Hg + 1/2O2 → HgO * |

| HgCL2 → HgCL2 * |

|

HgO* + H2SO4 * → HgSO4 * |

Dust control:

The adsorber also acts as a particulate control device and keeps particulates at low level. |

| |

|

| |

|